The access control system is one of the most commonly used systems in electronic door control using a card or a magnetic stripe that can be accessed by swiping through a reader on the door. These access control systems are used for security purposes. It is widely used in Offices, Server rooms, Homes, Airports, Defence, Data centers, etc.

The RFID tag in any form factor is being used as a pass to enter or exit a specific location; RFID reader fixed at the gateway sends electromagnetic waves and activates the RFID tag. A person with RFID tag (in card form or any) can gain access to an area bypassing tag over the fixed reader. The reader verifies the details stored on the IC of the RFID tag and allows the person to pass if verified.

Benefits of RFID based Access Control:

- Secure access to the workplace and residential complexes

- Controlled access to dangerous/secure equipment including vehicles and public transport

- Access to leisure and recreational facilities such as gymnasiums and sports clubs.

Animals move from one farm to another and their movement cannot be controlled or stored like any other product. The manual process of data entering about the number of animals enters and exit from the farm is time consuming resulting in more possibilities of errors. RFID Technology is largely used nowadays to track and record animal information, where direct line-of-sight is not practical.

RFID based Animal Tracking and identification are used the world over to track history and movement of farm animals, zoo animals, and pet animals. It is necessary to maintain records regarding animal origin, health, nutrition, the threat of disease and so on. These records ensure timely and proper feeding, vaccinating and transferring of animals between farms. Manual data entry is time-consuming and prone to high errors. These challenges are overcome through the adoption of RFID technology which automates and quickens the process of feeding, weighing, disease control, subsidies, breeding practices as well as quality and traceability assurance. It also ensures accurate data recording and efficient animal management.

Benefits of using RFID tags for livestock management:

- Verify the details of tagged animals

- Automate handling at farm and auction house.

- Supports Disease control

- Keep a track of the movement of animals

- No direct line of sight required

RFID has become the easiest way to keep track of your assets and maintain its database. Most companies store relevant information about their assets through RFID. Every company needs to track its assets!

How RFID based Asset Tracking process works?

Companies can keep a record of their assets; also can track their movement in and out of a gateway through RFID. For Example- A warehouse full of inventory, any company would require a record of the assets. RFID is the easiest way to record and maintain the data of multiple objects at once. The company can tag every object in the warehouse; each tag consists of a unique identity number to represent the tagged material. We can manually store the data on the IC of RFID tag and retrieve it automatically using a reader when required. The type of data stored on the tag could include- a type of material, date, time, etc.

The RFID systems provide a non-contact, non-line of sight method of automatically gathering, inspecting and distributing detailed production information and are capable of reading through metallic and non-metallic objects, such as plastic conveyors. Built for reliable operation under rugged conditions, RFID systems take on a wide range of operating conditions, including harsh environments, where barcoding is not practical. RFID Tags, RFID antennas and RFID controllers are all industrially ruggedized to withstand wet, oily and other adverse conditions.

Benefits of RFID based Asset tracking:

- No Direct Line of Sight – An RFID reader doesn’t need a line of sight for it to function; it just has to be within the range of the tag.

- Durability- These tags are capable of reading through metallic and non-metallic objects, such as plastic conveyors. Also, works under rugged conditions and harsh environment.

- Alignment– Read reliability of RFID is not affected by a misaligned tag.

- Reusability- Read/write tags can be modified by the RFID reader, making it possible to add or change information stored on the tag when necessary.

RFID technology to track baggage has been on the aviation industry’s radar screen for years. However, never before has industry-wide adoption been so close. Earlier this year at the Annual General Meeting (AGM) of the International Air Transport Association (IATA) its members agreed to consider expanding IATA’s existing baggage tag standards to include RFID inlays to enable real-time tracking of baggage.

Aviation Industry mostly faces an issue with baggage handling such as lost baggage and damage to belongings. To overcome such a problem, they need to tag the passenger’s bag to ensure baggage safety. A system is designed at both the security check-in and check-out point, an RFID tag is attached to the baggage of each passenger with their database. The reader at security points transmits data from tag to the system. The RFID tag attached to the baggage ensures the safety of the passenger’s belongings.

Benefits of using RFID for Baggage Handling:

- Increase baggage handling efficiency and reduce costs

- Cost-effective and easier process of baggage handling.

- Increase satisfaction among travelers.

- Reduce the risk of mishandled or lost luggage

In order for draught beer to reach retail outlets, a sophisticated logistics network must run from the breweries through the distributors and wholesalers all the way to where it is consumed. This draught beer is transported in beer kegs and tracking of these containers which are delivered to pubs, bars, restaurants, etc. involve a major effort. Beer keg tracking forms the basis of an efficient keg management system to ensure timely and effective distribution and delivery.

Omnia Technologies has developed special ferrite core-based transponders for beer keg tracking applications. The robust tag features an advanced anti-collision algorithm and operates effectively even on metallic surfaces. Omnia’s Beer Keg tag has a special housing to protect the RFID electronic component from mechanical stress which it is subjected ro throughout a keg’s lifecycle, in particular during washing and filling operations.

Benefits of Beer Keg Management by RFID:

- Reduced keg loss

- Improved turn rates

- More accurate inventory numbers

- Better decisions about target markets

Containers used for shipping goods are valuable assets themselves. Profitability is correlated with optimal usage of resources as well as return on investment. Shipping containers are usually bulky and extremely large in number making manual tracking difficult and prone to error. Further, shipping across countries and continents involving multiple organizations, legal frameworks and systems creates hindrances in controlling movement of containers as well as theft/loss or property.

RFID technology can assist in making this process more seamless and smooth. RFID tags are a suitable and cost effective method for universal implementation of electronic security seals.

Benefits of Container Tracking using RFID Technology:

- Accurate and timely shipping of goods with real-time tracking updates

- Verifying goods during loading and off-loading including en-route monitoring of seals

- Capturing complete logistics information trail

- Recovering reusable containers accurately through proper planning and tracking

- Higher return on investment of containers and reduced need for higher stock keeping

Toll collection is a part of government activity which includes collecting taxes from road users. Manual Toll collection activities lead to a long line on the highway. Also, this process creates congestion on the roads and thus more pollution from the vehicles.

Electronic Toll Collection system allows electronically charging a toll to an established customer account. ETC allows vehicles to pass through a toll without stopping or requiring any action by the driver. The automatic toll collection requires an account with the concerned government authority. RFID Tag with a chip in it is fixed on the windshield of the vehicle and enables a customer to make the toll payment directly from the account linked to the tag.

To conclude, Electronic Toll Collection is an RFID based toll collection system where every vehicle owns a unique identification number linked to a tag. When the vehicle enters the electromagnetic waves of the reader it automatically deducts a certain amount from the linked prepaid account and opens the gate for the vehicle to pass. This system includes an Electronic toll collection (ETC) system, real-time toll collection, and anti-theft solution system. This reduces manual labor and delays that often occur on roads. Electronic toll collection systems using RFID is an effective measure to reduce management costs and fees, at the same time, greatly reduce noise and pollution of a toll station.

Benefits of Electronic Toll Collection:

- Faster & efficient movement of vehicles

- It helps in monitoring every vehicle which enters and exits.

- Will reduce the congestion on the road.

- Using RFID Tags for Toll collection is a part of Smart City projects as well.

Food quality has become an important issue in the last decade. However, achieving end‐to‐end traceability across the supply chain is currently quite a challenge from a technical, co‐ordination and a cost perspective. The paper contributes by suggesting a specific technological approach, exploiting the new possibilities provided by RFID technology, to address these issues.

Across the globe, Regulations that mandate the ability to trace the origins of food are being put in place to control the food chain, provide safer food supplies, and prevent bioterrorism.

Benefits with RFID:

- Meet traceability compliance deadlines.

- Integrate agricultural firms into the food chain.

- Reduce product recall costs with case-level RFID tags.

Omnia provides a number of LF and UHF tags which can be used in food traceability for packaged food and crate identification

The deployment of RFID technology enables gas cylinder identification and management through the supply chain. It helps create a transparent supply chain through accurate data records. It links the assigned cylinder with its user and helps in quick and easier usage identification and billing. RFID tracking also assists in monitoring the movement of cylinders. This helps in inventor optimization through better allocation of resources and with less logistical efforts. In fact, it eliminates scope for malicious intent or manual error due to carelessness. Overall, RFID tags can be used effectively to monitor, track and bill for gas cylinders quickly and accurately.

Benefits of Cylinder Tracking with RFID:

- Automate the whole working process involved in the organization.

- Tracking of Cylinders in Warehouse, Cylinders in transit for delivery, Cylinders delivered, Cylinders returned back to the warehouse.

- Cylinder stock can be tracked at the click of a button.

- Real-time visibility of stocks & location of cylinders.

- The complete history of the cylinders helps to identify the cylinders which are due for testing.

- The decrease in lost cylinders.

- The system is capable to prevent pilferage/theft of cylinders.

Hospital equipment tracking, as well as patient tracking, are essential for safe and proper management of resources and treatments in a hospital. For hospital equipment, RFID tags can be used to track inventory, locate assets, follow maintenance cycles, and optimize equipment usage across the hospital for different procedures. Enhanced visibility and traceability through RFID help in reduction in loss of equipment allowing hospitals to stock lower levels of this equipment and tools.

RFID Technology plays a crucial role in the pharma & health-care industry, it includes equipment tracking, people identification and tracking, medical report monitoring, medicine tracking, and supply chain.

Benefits of using RFID in hospital equipment tracking:

- RFID is an asset visibility solution to make the work process simpler. By tracking and identifying assets through RFID hospitals can make it easier for staff to find idle equipment and avoid the purchase of unnecessary capital.

- RFID tags on hospital equipment help in keeping an account of inventories. RFID provides improved visibility of pharmaceuticals, implants, surgical instruments, and other items that can be difficult to track manually. Keeping count of inventory saves time and ensures that facilities never run low on important items.

- RFID tags make it easier for medical equipment to be tracked and traced, enabling hospital employees to easily locate equipment when it is required urgently, thereby enhancing the safety of patients.

With increasing complexities in the work process, managing inventory has become tough and important too. An inventory management system helps a company to have clear insights into the stock in hand; it prevents stock surplus or its shortage, stock security and quality management. Inventory visibility and control are keys to maximizing throughput and boosting productivity. Radiofrequency identification (RFID) is a technology that creates visibility and helps in controlling the inventory at the warehouse.

RFID technology helps in the identification and recording of individual products and components, and to track them throughout the verticals from production to point-of-sale. This process does not require direct line-of-sight and it creates visibility of stock in hand, thus helps proper utilization to it. Every movement of the inventory/stock can be automatically stored on the system with the help of this technology.

Benefits of Inventory Management using RFID Technology:

- Enhanced productivity through real-time visibility of inventory.

- Every movement of inventory in and out of the store can be tracked.

- Reduce chances of over-stocking or under-stocking.

- Optimum utilization of resources.

- Helps in reducing inventory storage cost.

IT Asset tracking is tracking the various IT asset of a company like a laptop, CPU, monitor, keyboard, etc. from the time of their purchase to the time of disposal.

Asset tracking enables you to identify and track the change in the location of assets, increase or decrease the number of assets, track assignment status and user information. Tracking IT assets allows getting maximum value from the use of the assets, right-size IT inventory, and optimizing inventory purchase decisions and strategies.

RFID Technology helps in tracking the IT Assets with a small tag attached to assets. Whenever these assets with the RFID tags come near to the reader, its data is automatically stored.

Benefits of IT Asset Tracking with RFID:

- Ensures the company’s assets and the data are secure.

- It helps in preventing inventory over-stocking and misuse.

- Real-time visibility of IT Assets allows management to improve efficiency and performance, by reducing the overheads.

Inventory management of jewelry is a crucial and time-consuming task. Jewelers tend to undertake inventory checking, accounting and record management on a daily or weekly basis across manufacturing, wholesale and retail sectors. Being very precious and valuable articles, even a few pieces of jewelry being misplaced or lost could lead to huge losses.

RFID Tagging of jewelry articles can assist in the quick, accurate and efficient management of these goods. RFID tagged jewelry items can be read in bulk which makes stock-taking and bookkeeping very quick and reduces the scope of manual error. These eliminated losses and also decreased manual labor.

A more advanced system for inventory management incorporates RFID and EAS technology which Omnia supports through its combination RFID + EAS tag. This not only helps avail the benefits of RFID technology but also prevents theft of the jewelry article through the Electronic Article Surveillance (EAS) technology. This dual-purpose tag is an innovative way to solve multiple problems faced by jewelers through a single solution.

Benefits of Jewelry Management with RFID:

- RFID near-field technology allows close and accurate monitoring and tracking.

- Automated inventory tracking & monitoring on a real-time basis.

- Accurate and replaces the time-consuming manual process.

- Provide a very high accuracy rate for item-level product/asset monitoring.

- Customization possible for jewelry outlets, goldsmiths and pawnshops in large/small scale implementation

Laundry Management system allows you to keep a track of in and out of laundry from an area. This tracking enables us to track the life span of fabric and keep an optimum level of fabric in stock. RFID Technology enables tracking of laundry by tagging it.

Omnia Technologies enables companies to automatically track linens, clothing, rags, and other assets in order to provide more accurate inventory management and accounting practices. These RFID tags are designed to meet all requirements in terms of pressure, heat and chemical resistance in the applications of contactless tracking of garments in the textile rental and dry cleaning.

Each Laundry Transponder has a unique identification number. The Transponder can be easily patched in all garments and minimize shortages. If a garment is lost while being processed, using RFID it can be identified. It saves handling time at on & off-site, soil laundry check-in and clean laundry check outstations. They provide end-users with a full service from renting to cleaning the supply of garments, laundering and collection/delivery services.

Benefits of Laundry Tracking/ Management:

- Real-time tracking of the laundry items from point of pick-up, through sorting, washing or dry-cleaning, packaging, and distribution.

- Reduced handling time at check in and check out on site and off site

- Automatic identification of misplaced and stolen items.

- Accurate data capture regarding item lifecycle, inventory control, reusable asset sterilization control as well as automatic billing to end users.

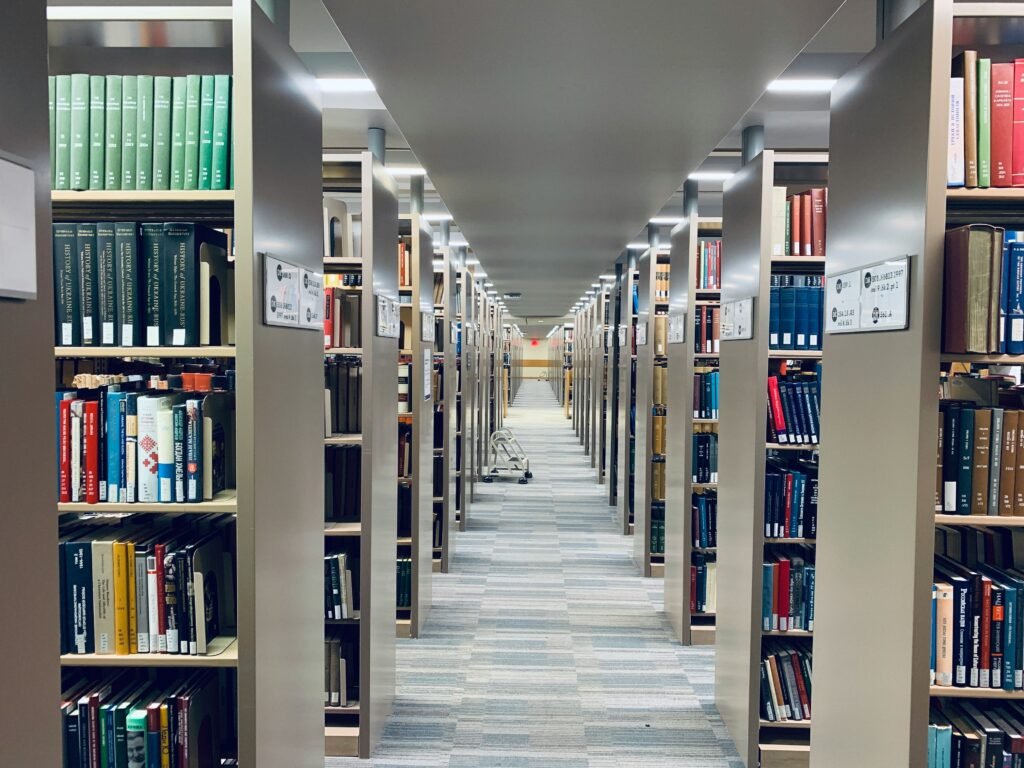

RFID is nowadays widely used in libraries for automation and security activities like- maintenance of documents either inside the library. Radio Frequency Identification Technology can also be used for library management. A library usually requires a tracking system to keep a check on material across the library. RFID based system supports the library in tracking and recording the transactions, it helps in monitoring and improving the handling process. RFID tags are attached to books & material in the library with their stored information on the chip.

RFID Technology uses a tag with an IC in it which contains all the information about the material tagged. Each RFID tag has a unique identification number. This tag is attached to material in the library and read using RFID reader regardless of alignment or orientation of the tag. These RFID tags are in different forms used according to the application, for Library management usually smart label tags are used. These are thin tags fixed inside the material in the library.

RFID-based systems have been implemented for efficient document tracking purposes throughout the libraries that combine, easier and faster charging and discharging of documents, the security of materials, inventorying, stock verification and shelf handling. RFID tag’s transponder listens for a radio query from the reader and responds by transmitting their unique ID code.

Benefits of RFID at Library:

- Reduces the transaction time; faster process.

- RFID makes material handling much easier.

- A great tracking and security system.

- Reduces the time of shelving and circulation.

Complex and large scale manufacturing entail constant monitoring of process and tracking WIP and inventory. This can be carried out successfully using RFID tags which bring a lot of transparency and traceability in the processes. These tags can be deployed to help in management of all assets on the assembly line from manufacturing machinery, equipment and tools to WIP and final goods produced. They help in data collection, maintaining accurate reports and records, finding inconsistencies in process or quality, tracking rework and rejected material and even proper and accurate dispatches. These benefits lead to overall efficiencies and time savings in the production process.

The benefits of incorporating RFID technology in the manufacturing process are:

- Better inventory management through enhanced visibility and control of resources

- Timely maintenance of manufacturing equipment leading to high longevity

- Identification of inefficiencies and reasons for loss/failure along the assembly line through analysis of data records collected using RFID tags.

- Life cycle management and accurate warranty processing through data collection and tracking of finished goods

It requires a technology called Near Field Communication (NFC), which is an extension of Radio frequency identification (RFID) technology that combines the interface of a smart card and a reader into a single device. This allows two-way communications between endpoints, where earlier systems were one-way.

For two devices to communicate using NFC one device must have an NFC reader/writer and one must have an NFC tag.

Benefits of Mobile Payment using NFC:

- Quick and easy payment method.

- Transactions are made only within close proximity, which makes the system a safer method of payment.

Pallet Tracking is essential to enhance productivity, cost efficiencies and track reusable assets to increase return on investment. Pallet movement contributes significantly towards the handling, transport and storage costs. As goods move on pallets through a warehouse or a supply chain, it becomes imperative to track their movement and collect information regarding their location, usage, process flow, and available inventory. Access to such critical information enables quick transportation of goods through optimal resource planning, accurate implementation, involving least handling time and cost.

This information can be recorded with the help of RFID tags which can be attached to the pallets or built into them. Omnia’s RFID tags for pallets are designed to withstand water, chemicals, and shock and temperature variation leading to excellent performance in harsh and outdoor environments.

Benefits of Pallet tracking using RFID Technology:

- Enhanced productivity through real-time visibility and control of pallets movement

- Improved stock tracking helps in efficient transport systems

- Reduced human error and loss of assets

- Cost efficiencies through speedy accurate tracking with reduced labor intervention

- Correct billing of goods based on accurate pallet movement leads to higher revenue

RFID windshield tags mounted on the windshield is specific to users, the details for each vehicle is mapped prior to the process. RFID technology allows for easy and fast communication between tag and reader. RFID readers are mounted on the entry and exit gate as the vehicle enters the range of the reader it activates the tag, the tag transfers the data from its IC to the system and allows entry or exit of the vehicle. This helps in allowing access to a vehicle to a secure gated parking lot, automates billing and electronic collection of parking fees, and eliminates the scope of misplacing parking tokens/tickets.

RFID based parking management will allow vehicles to move without having to stop. Drivers will not have to stop at the point of circulation and parking tickets will be out of usage during entry-point and exit-point. The amount will be automatically deducted from the user’s account as the vehicle passes the gate, they can recharge their account according to requirement. Since there won’t be any waiting during Entry-point and exit-points the pollution problem will be avoided.

Benefits of RFID based Parking Management:

- Reduces the chances of human error.

- Fasten the process of entry and exit.

- Reduce the traffic on roads

- Reduces pollution

- Enhanced safety and security by allowing access to authorized people.

Doctors and hospitals are adopting high levels of automation in the treatment process. This is not restricted to the equipment they use to diagnose a patient or to carry out procedures, but also to track patients and their treatment. Healthcare systems are a very important part of the economy of any country and for public health. RFID technology implements smart patient management, monitoring, and tracking process that can be used in hospitals to automate and organize their information management.

Patients are made to wear RFID Wristband tags which are stored with information regarding their diagnosis, medical history, and treatment process. These RFID tags consist of unique identification numbers for each patient which will identify her/him in the health information system. As the patient moves through different steps in his treatment process, these tags become a medium to automatically identify the patient and retrieve information regarding treatment, medication cycle and also update records as and when the treatment progresses; it is saved in a database for further analysis.

Benefits of Patient Tracking through RFID:

- Better tracking of the treatment process

- Enhancing internal schedules

- Accumulated RFID data can help a healthcare organization in predicting patient flow.

- The system increases patient safety by reducing human error and so improves the efficiency of the service

- Analysing the data about a patient’s movements can help the hospital for deeper insights.

In events management, RFID wristbands are used on a large scale to record entry-exit of visitors and monitor their movement. These wristband tags having unique ids can store visitor information. With RFID readers installed in multiple locations at the event, it becomes easy to track visitors’ movement.

For events such as exhibitions, data collection regarding their movement helps exhibitors and organizers study footfall, movement patterns, areas of interest of visitors across various market verticals. It also helps with branding activities as many companies enjoy sponsoring this RFID taggingactivity and acknowledging the arrival of visitors at multiple locations through TV pop ups. In concerts, these wristband tags can have attendee information stored regarding access, food and beverage package, etc. This helps in maintaining limited access to restricted areas and also in cashless transactions respectively.

Some more unique applications also make use of RFID wristband tags for identification and tracking of people. These include tracking of children’s movement in amusement parks and on beaches and tracking patients within hospitals or rehabilitation centers.

Benefits with RFID:

- Enables quick, contactless entry and secure access to restricted areas.

- Tracks movement of visitors, patients, or children.

- Supports cashless transactions and enhances user convenience.

Counterfeit pharmaceutical is one of the most critical issues facing the pharmaceutical industry today. The business of selling fake drugs is escalating globally. Adoption of RFID hardware and software throughout the pharmaceutical industry from manufacturing to distribution and sale/consumption can help overcome this dangerous problem. Reliable, accurate and secure measures for tracking, tracing and authenticating pharma products across the supply chain are essential to protect consumers as well as pharmaceutical manufacturers’ brands.

When the manufacturer puts an RFID tag on the product, it stores all the static information about the product such as a lot number and expiry dates in a database for record-keeping. When the product moves across the supply chain, from the manufacturer to the wholesaler, this information of the tags is updated in the database holding the initial information.

This process is carried out through all phases of the movement of drugs, from the wholesalers to the distributors, to the hospitals and pharmacies. It increases visibility, traceability, and authentication of products to safeguard consumers’ health and protect the pharmaceutical industry overall.

Contactless radio frequency identification (RFID) systems provide a secure and convenient solution for a number of animal identification applications including livestock tracking, and the tagging of pets and racing pigeons For pigeon racing, electronic pigeon rings are used for fraud protection at pigeon races. To prevent fraud, the tags need to be encoded and as a result, authentication issues play a major role in this market.

Benefits of RFID in Tracking Pigeons:

- Secure authentication of animals.

- Detect several animals at the same time within one antenna.

- Offline data storage through additional memory.

- Fast delivery and lean logistics flow for transponder production through application of the ISO animal number just in time (OTP functionality).

- Best in class read/write operating range.

Public transportation systems primarily involve controlled access, recording movement of passengers and ensuring fare collection. Across the world, these systems are automated or semi-automated and this involves the utilization of RFID Technology. RFID Tags are geared to perform all these functions and cater to the needs of such systems.

Tags can in the form of Smart Tickets, AFC tokens, or RFID enabled contactless cards. All these tags offer benefits of low-cost reusable tags, collection of accurate data, and quick and efficient movement of passengers. The need for manual intervention is also lower and accounting records are better maintained with respect to cash collections.

RFID tags can be used across railways, metros, buses among other public transport systems.

Benefits with RFID:

- Enables fast, contactless travel with RFID tags or tokens.

- Ensures accurate fare collection with minimal manual input.

- Provides reusable, low-cost tags

Radiofrequency identification is being adopted rapidly in a growing number of tire industry processes and will deliver more transparency, fewer rejected tires and production failures and better control of materials. Major tire producers are investigating new technologies to support their internal production processes and to gather more data per process step for individual tires.

RFID is changing the tire industry for the better and regulations are influencing tire manufacturers to make the required changes and implement RFID to provide further transparency into the tire supply chain.

RFID is helping manufacturers to identify, track, and manage tires all through their production and distribution processes, increasing read rates, cutting labor costs, reducing scrap and rework.

Omnia manufacturers two types of RFID tire tags: The UHF Spring tire tag is inserted inside the tire at the time of tire manufacturing (during the vulcanization process) and is therefore protected against tampering and outside elements. If the tire is already manufactured then this cannot be inserted, in this case, we put the spring tire tag in a patch and put this patch on the inside wall of the tire using a cold, chemical or heat cure process(this is just like patch, we use for putting a puncture on the tire).

Warehouse management is imperative across all industries and market verticals. RFID nowadays has become a significant part of warehouse management. It provides advantages to a warehouse by tracking, securing and managing items from the time they enter the yard/warehouse through the entire transit. Warehouse agents can benefit from RFID tags because this technology can make internal processes more efficient and improve responsiveness, by enabling real-time traceability of assets.

RFID tags can create such systems which are reliable and bring about efficiencies along these warehouse and distribution channels. Also, it monitors the progress of products through the warehouse through automatic identification of goods, maintaining accurate and timely records of their location, movement, dispatches, and delivery. RFID tags are attached to the materials, RFID Readers and Antennas are installed at the checkpoints which typically would be the entry/exit points of the warehouse; to record the movement of tagged assets.

A regular inventory update is possible by using handheld RFID devices, during the life span of the material in the warehouse. The data can be automatically updated for a lot of material at once. RFID technology holds the capacity of reading multiple (>100) tags simultaneously. Constant monitoring of the materials will be possible at any time by increasing the number of readers and antennas.

Benefits of RFID based Warehouse Management:

- Provide greater visibility of the inventory as it moves.

- Enable faster inventory turns and less stagnant stock.

- Reduces inventory handling costs.

- RFID Technology increases the speed and productivity of the tracking process in warehouses, reduces the need for manual checks and counts.

- Capture critical information to and from every point of activity.

- Reduces inventory errors and inaccuracies

Radio frequency identification (RFID) is a powerful tool for waste collection, disposal, and management of waste, delivering different benefits to city governments and waste removal contractors. The technology enhances the efficiency of the waste management process. RFID encourages traceability and real-time visibility in waste management operations.

Omnia Technologies offers a broad spectrum of LF and UHF passive contactless transponders that provide various levels of resistance to water, shock, and temperature variation making the tags suitable for harsh and outdoor environments. Waste bins that have RFID tags fitted in them are picked up by disposal trucks equipped with RFID readers. These readers record the exact time and place every time a waste bin is emptied. This automatic data collection makes data reporting cheaper, faster and accurate.

How RFID Technology works for Waste Management:

RFID Tags are attached to the waste bin at every household in all regions. This RFID tag contains a unique Identification which represents each household’s customer information. Also a reader, antenna and scale are mounted on a garbage truck. The reader and antenna communicate with the RFID tags. The RFID tag, located on the cart, transmits its unique ID. The reader on the truck will receive this ID as each waste bin is emptied, weighs the bin. Data collected from the tags, which can be linked with a timestamp, type of container, weight of the container, truck’s identity, load description and customer information, can also be stored in the truck’s onboard computer and later transferred to a central waste management system for data processing or can be directly to a host computer.

Benefits of Waste Management using RFID Technology:

- It helps track waste collection and container movement, monitors sorting quality, and improves overall efficiencies.

- Quickens and simplifies the process of billing for services rendered and allows easy implementation of incentive programs

- Enables municipalities to evaluate the performance of subcontractors and have unprecedented control of the waste-disposal process.